Established in 1968, EPC has been in the custom injection molding business for over 50 years. Our values are what have made us successful, along with our dedication to use the most current technology at every stage of manufacturing and management process.

In these ways, EPC is positioned to serve our customer’s needs today and into the future.

Consider Engineered Plastics.

There are probably a few things we haven’t seen…but not many. Our team of professionals is dedicated to serving your needs, guided by our core values of quality, customer service and competitive pricing.

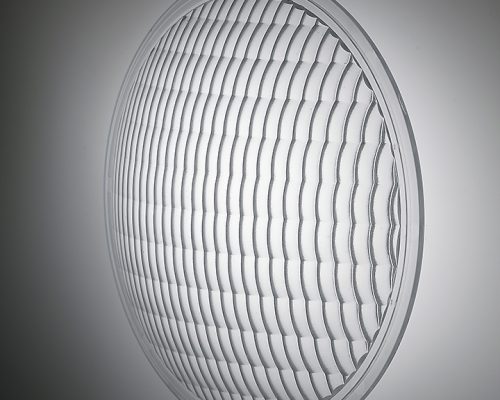

The Art and Soul of Injection Molding.

Our experience gives us the ability to conquer the most complicated designs in the most deliberate, efficient manner.

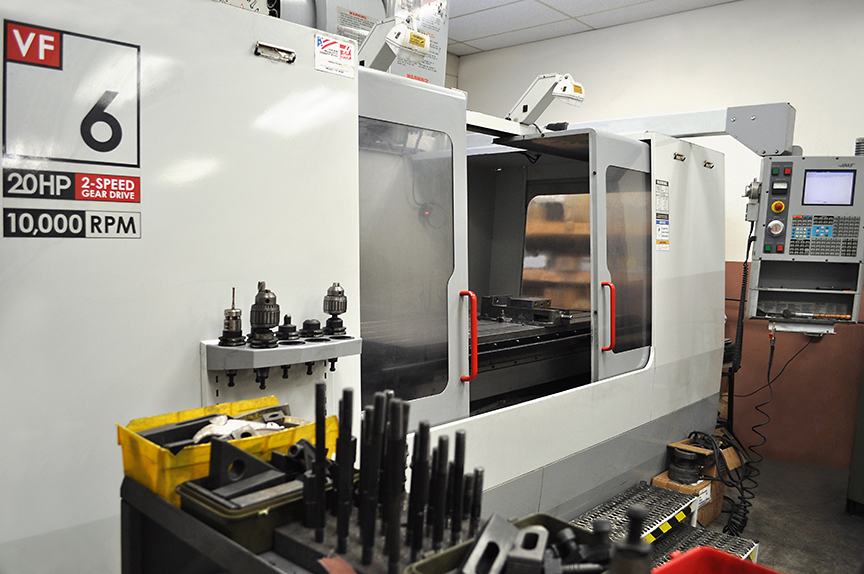

The Key to Quality

At EPC, the transition from design to tool making is effectively carried out with the use of the most advanced construction equipment and software. We employ the use of wire EDM and traditional EDM technologies; CNC milling equipment and integrated software; along with traditional tool making methods.

EPC directs an efficient construction process that maintains critically high standards while controlling costs and deliveries. The result is a tool that produces parts of consistent quality through each and every production

EPC maintains all tools to ensure long life and consistent part quality during production.

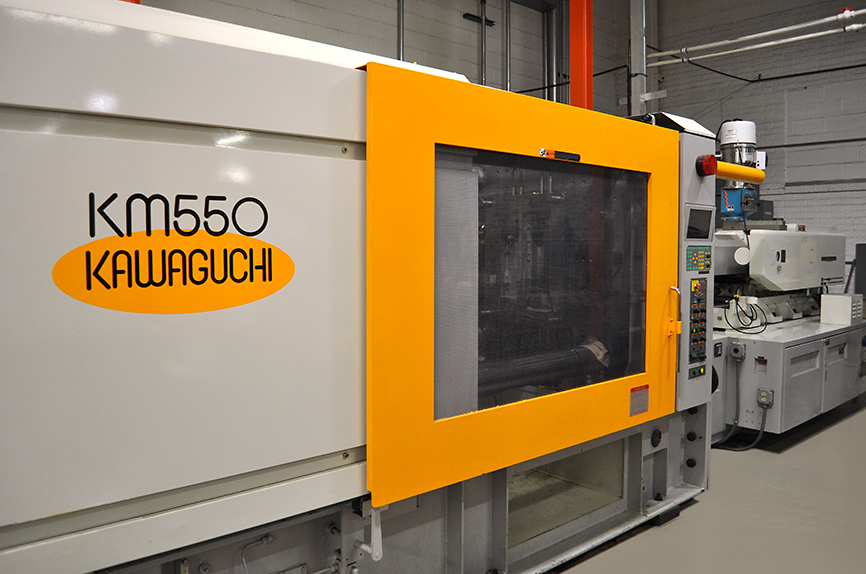

Large and Small Around the Clock

Automation and flexibility are the keys to cost effective production and minimized lead times. With an ongoing dedication to state-of-the-art machinery, EPC can meet your needs.

Calculated Consistency and Confidence

Our quality control methods are designed to meet the most stringent industry standards.

These add to our wide array of molding machines ranging from 50 to 500 tons with shot capacities to 60 ounces. Our facility operates three shifts, 24 hours a day. We are able to handle any size production run in a competitive market.

EPC processes most engineered and commodity resins and specializes in many advanced and exotic resins solutions. With advanced material compounding, we have employed plastics that supersede most high temperature, high wear, and high strength materials commercially available in today’s market.

Secondary Options Under One Roof

Assembly

Hot Stamping

Ultrasonic Welding

Drilling and Tapping

Silk Screening

Pad Printing

Machining

Engraving

Insert Molding

Tooling

Tooling